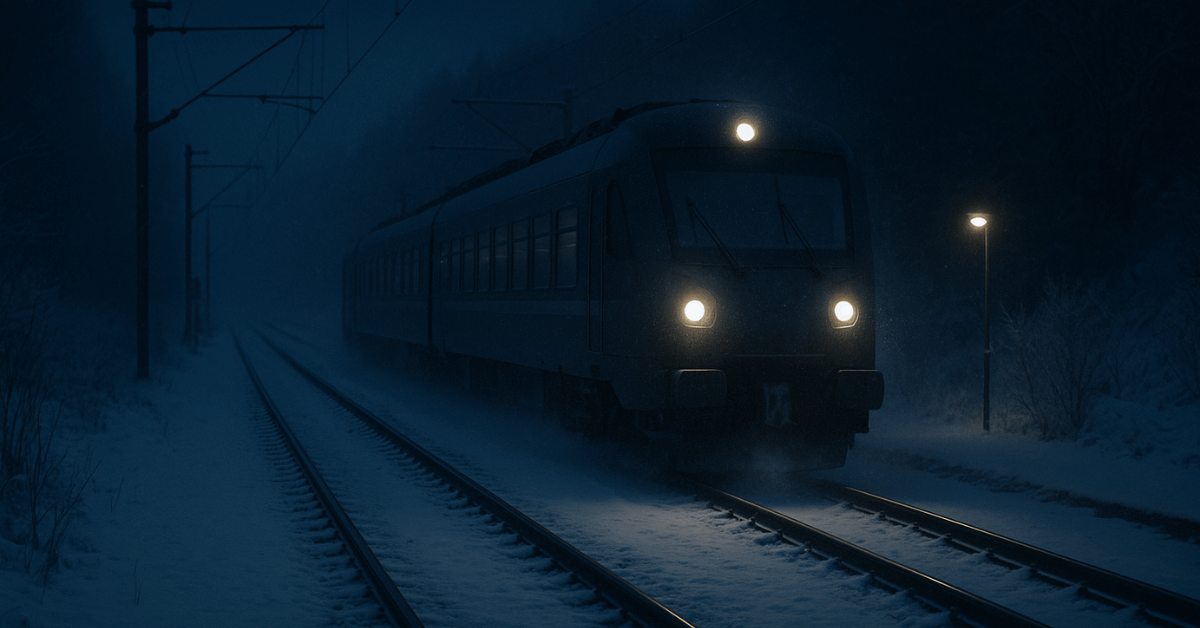

Harsh weather in upland corridors changes how trains run and how passengers plan.

Winter Schedule Adjustment for Hill Region Trains typically means earlier starts, tighter turnarounds, and engineered protections for track equipment when snow and ice arrive.

Planning around these shifts reduces missed connections and helps preserve capacity during the most fragile months. Expect operator-specific variations driven by geography, elevation, and current infrastructure.

What Changes in Winter, and Why It’s Standard Practice

Rail networks refresh their base timetables twice a year to synchronize maintenance, service patterns, and international connections.

In the UK and much of Europe, the long-standing convention sets a December change and a mid-year update; the European legal framework fixes the winter timetable change date at midnight on the second Saturday in December, with an additional June slot for adjustments.

Hill routes experience extra stress in winter: lower rail adhesion, drifting snow, and points (switches) freezing. Operators mitigate risk using cold weather rail safety measures such as points heating, insulation, and de-icing trains—techniques documented by Network Rail and partner operators.

Common Winter Schedule Adjustments

Seasonal tweaks aim to preserve reliability when margins shrink. Capacity, crew, and rolling-stock cycles are re-timed to keep frequency credible in bad weather.

Expect these patterns to appear in many hill regions:

- Speed restrictions during frozen periods are used to manage braking and signaling safety, which can extend runtimes.

- Early departures on first-wave trains to protect peak capacity and absorb slow running on steep grades.

- Shortened or extended dwell times at intermediate stations when conditions require platform clearing or door de-icing.

- Additional reserve trains are staged near vulnerable segments to replace failed units or run recovery trips.

- Intermediate turnarounds and compressed turnaround time so trains can short-turn before blocked sections and re-enter service sooner—common in metro and regional recovery playbooks.

How Operators Prepare Infrastructure and Fleets

Winter reliability on hill lines depends on proactive engineering and disciplined overnight operations. Neglecting either creates day-long cascades of delay when the first snowfall hits.

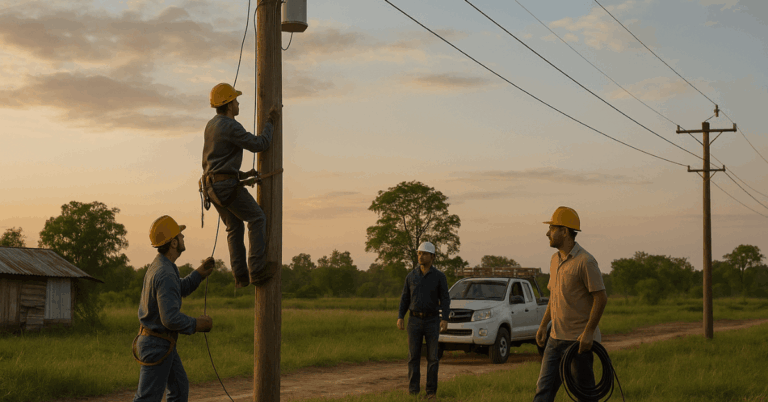

Heaters, Insulation, and Avalanche Protection

Points are fitted with electric heaters, point heaters, and insulation to prevent ice binding in turnouts—the most failure-prone assets during freeze-thaw cycles. In the Scottish uplands, avalanche shelters protect vulnerable cuttings and portals.

“Ghost” Trains and Track Treatment

Empty trains—widely called ghost trains in winter—run overnight to keep rails polished and ice-free; specialist units spray anti-icing fluid or provide third-rail de-icing where applicable.

Network Rail confirms both practices are standard in cold patterns, and industry managers consistently highlight them as effective mitigations.

“We work closely with train operators to minimise any impact on passenger services during winter weather such as snow and ice.” — Network Rail operations leadership.

Snowploughs, Route-Proving, and Depth Limits

Small snow ploughs can be attached to the front of passenger trains to clear up to eight inches of snow; heavier snow blowers and plough locomotives take over in deeper drifts. These vehicles also perform “route proving” passes before the morning peak on susceptible gradients.

Timetable Cadence and What It Means This Season

National frameworks anchor the calendar so operators can publish in sync and passengers can plan. The UK National Rail base timetable in 2025 runs 18 May–13 December 2025, with the next issue set for 14 December 2025–16 May 2026.

For daily travel decisions, the published timetable of the day appears by 22:00 on the previous evening and supersedes printed leaflets or static PDFs.

European law explains the coordination: the working timetable changes annually at midnight on the second Saturday in December, and post-winter adjustments may occur at the same time in June.

Example: 2025–2026 UK Changes That Affect Upland Corridors

Britain’s rail industry plans the largest East Coast Main Line update in more than a decade, starting Sunday, 14 December 2025, adding frequency, cutting journey times, and delivering thousands of extra seats daily, benefits that ripple to feeder services across northern hills and the Scottish borders.

The project cites about 16,000 additional seats per day on the corridor.

National Rail’s operator-by-operator summary lists cross-country uplifts, retimings on Great Northern/Thameslink, and additional Sunday capacity on long-distance flows, while noting engineering works over Christmas may delay full rollout until February 2026 on some routes.

Planning Guidance for Hill and Mountain Travel

Preparation matters more than optimism when snow threatens to degrade uphill performance. The steps below compress the essentials for daily and occasional users.

Quick actions that prevent missed trains and tight connections:

- Check the published timetable of the day after 22:00 local time and again before leaving, as overnight mitigation may insert or cancel services.

- Build a 15–30 minute buffer for uphill segments where speed restrictions or door de-icing extend dwell times in cold snaps.

- Prefer earlier first-wave departures during warnings; these often carry timetable padding to protect peak capacity on grades.

- Watch mountain rail service updates on operator feeds for short-turns that alter terminal stops and bus bridges over passes.

- Keep an eye on snow and ice train operations notices that trigger ghost runs and plough activity; such alerts frequently predict morning headway changes.

Rolling-Stock Cycles and Turnbacks in Disruption

Academic and industry studies treat short-turning and skip-stop as standard recovery tools; both reduce passenger delay when a single snow-choked section would otherwise collapse the line.

When turnbacks are used aggressively, terminal headways widen slightly, but overall network waiting time drops.

Compressed turnarounds at termini or pocket tracks also keep diagrams tight during reduced speeds. The practice increases utilization, yet requires reliable points heating and clear route-proving passes in the hour before service.

Operator Engineering: What to Look For in Notices

Many infrastructure managers publish seasonal engineering rundowns. Signals of robust winter readiness include: heated and insulated points at high-elevation junctions, static de-icers at known “black spots,” and published thresholds for when snowplough-equipped trains take over.

Government and regulator documents across Europe explicitly reference these measures in winter management plans.

Where routes interline with mainlines undergoing timetable upgrades, such as the East Coast Main Line in late 2025, hill services often inherit better slots and more even spacing once the base plan stabilizes. Checking operator bulletins alongside national timetable pages offers the clearest picture during rollout weeks.

Conclusion

Reliable travel in upland corridors remains possible when seasonal engineering and schedule discipline work together.

The Winter Schedule Adjustment for Hill Region Trains reflects proven techniques, heated points, ghost runs, and snowploughs, combined with calendar rules that keep entire networks synchronized.

Confirm the published timetable of the day, leave realistic buffers during warnings, and expect short-turns or capacity shifts when snowfall intensifies on grades. The combination delivers safer operations and steadier service through the coldest months.