Rail networks worldwide are investing in Safety Upgrades on Long-Distance Trains to cut collision risk, improve incident response, and harden rolling stock against fire and impact.

Modern signaling, crashworthy designs, and data-driven maintenance now work together rather than as isolated projects.

Expect the biggest gains where operators pair control-system automation with infrastructure fixes and disciplined operating practices.

What Counts as Upgrades Today?

Modern programs span four layers: technology and control, infrastructure and track, train design and materials, plus operations and passenger communication.

Advanced signaling and communication move decision-making into the cab, while automation enforces limits when human vigilance slips. Infrastructure upgrades focus on track condition, level crossing elimination, and trespass prevention.

Crash-energy management and fire-safe interiors protect occupants when prevention fails. Finally, staff training, automated inspection, and passenger emergency alerts accelerate detection, response, and recovery.

Technology and Control Systems

A coordinated technology stack reduces human-error exposure and enforces movement authority.

Plan to evaluate each line’s hazards, then deploy the matching level of protection, intermittent warnings on lower-risk routes, continuous supervision on high-speed or dense corridors, and overlay systems where interoperability demands it.

Automated signaling and communication

Digital interlockings, continuous speed supervision, and in-cab signaling systems shrink reaction time and remove ambiguity.

Continuous cab displays and enforced braking thresholds outperform lineside signals alone, especially at night and in poor visibility.

The European Rail Traffic Management System standardizes this approach for cross-border operations by unifying signaling and speed control under one interoperable framework.

Positive Train Control (PTC)

North American corridors use positive train control to automatically prevent train-to-train collisions, overspeed derailments, incursions into work zones, and movements through misaligned switches.

FRA confirms full implementation on all mandated U.S. route-miles, with ongoing compliance under 49 CFR Part 236 Subpart I.

Train Collision Avoidance System and ATC

Several countries apply an indigenous train collision avoidance system that supervises authority, speed, and signal adherence; India’s Kavach (formerly TCAS) is a current example with SIL-4 certification and active national rollout.

Automatic Train Control (ATC) variants deliver similar enforcement on legacy networks.

ERTMS, LZB, and national ATPs

Cross-border Europe increasingly favors ERTMS Levels 1–2; Germany and Spain still operate LZB on selected high-speed routes; Spain’s ASFA provides intermittent ATP on conventional lines and a digital evolution for better supervision.

Selecting among these depends on the required speed, capacity, and migration constraints.

AI, IoT, and Predictive Maintenance

Sensors on rolling stock and wayside assets stream data on vibration, temperature, geometry, and current draw. Analytics rank anomalies, flagging defects days or weeks ahead of failure.

Treat predictive maintenance for railways as a safety program first and a cost program second, since the largest benefits come from avoided incidents and fewer service-disrupting failures.

FRA’s Automated Track Inspection Program (ATIP) demonstrates the value: autonomous survey cars scan track condition at scale, enabling targeted maintenance and enforcement.

Infrastructure and Track Safety

Complex networks demand steady investment in right-of-way condition and safe road–rail interfaces. Building the right civil works and removing conflict points often delivers the fastest reduction in fatalities.

Track renewal and inspection

Rail, sleepers, ballast, and geometry must hold tolerances under long-distance loads. Automated inspection cars and portable instrumentation complement visual patrols, catching gauge spread, surface defects, and alignment drift early.

FRA operates ATIP to audit compliance and trend risk across the national network, reinforcing continuous quality improvement.

Level crossings and grade separations

Converting high-risk crossings to overpasses or underpasses cuts exposure dramatically.

Where full separation isn’t feasible, upgrade to active protection—flashing lights, automated gates, constant-warning-time predictors, and obstruction detection—then tie maintenance to risk.

The U.S. Section 130 Railway-Highway Crossings Program reports a 41% reduction in fatalities from 2000 to 2023 associated with funded improvements. FRA still records more than 2,000 incidents and roughly 200 fatalities annually, underscoring the need to prioritize hotspots.

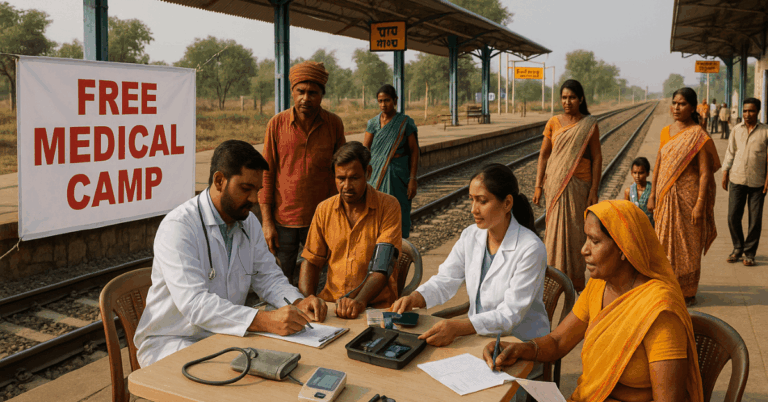

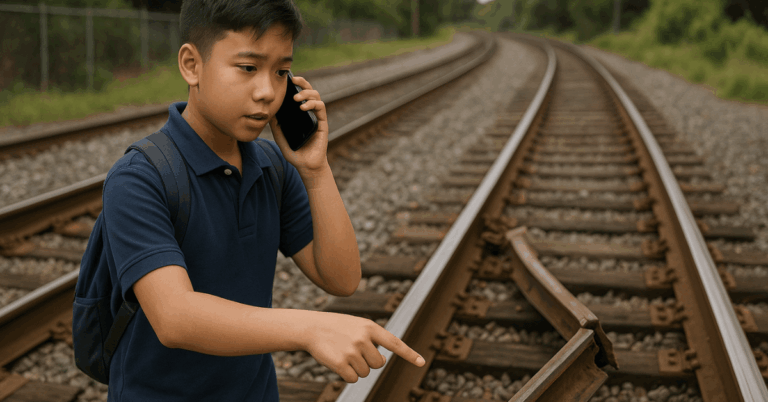

Trespass and trackside fencing

Good fencing, clear sightlines, and community education reduce trespass and animal incursions.

EU safety reports show unauthorized persons and level-crossing events remain major contributors to fatalities, supporting investment in prevention alongside enforcement.

Train Design and Materials

Passive safety mitigations protect occupants when prevention layers fail. Crash-energy management structures absorb impact outside the passenger space, while interior fixtures resist detachment.

Modern rolling stock in Europe follows EN 15227 (crashworthiness), integrating energy-absorbing modules and survival-space criteria; fire performance is addressed by EN 45545, which governs materials and assemblies. U.S. requirements appear in 49 CFR Part 238, including crashworthiness, occupant protection, and emergency lighting.

These aligned frameworks drive designs with crumple zones, anchored seating, break-away fittings, low-smoke/toxicity materials, and integrated evacuation paths.

Operations, Training, and Automated Inspection

Strong procedures sustain technology benefits. Regular recertification, simulation drills, and rules compliance keep crews proficient with braking curves, restricted-speed movement, and degraded-mode operation.

Automated track inspection complements human patrols by surveying geometry at speed, improving coverage and consistency versus manual-only programs.

U.S. passenger equipment rules further codify inspection and reliability-based maintenance, linking fleet availability to safety performance.

Passenger-Facing Safety and Communication

Clear, timely information reduces panic and speeds self-evacuation.

Standard practice now includes multi-channel notifications, onboard displays, PA announcements, SMS/app push messages, and staff-device workflows to guide actions during medical events, fires, or external hazards.

Hazardous materials response adds a separate responder channel; U.S. authorities encourage tools that provide real-time consistent information to 9-1-1 centers for faster, safer decision-making.

Funding, Regulation, and Governance

Sustained safety gains rely on stable funding and independent oversight.

National regulators define minimum performance targets and certify systems; in the U.S., FRA governs passenger-equipment standards and PTC rules, while in Europe, the European Union Agency for Railways steers ERTMS and interoperability.

Crossing upgrades often blend federal and local funds, with Section 130 in the U.S. or national programs in other regions underwriting separations, active protection, and data-led risk reviews.

Conclusion

Long-distance rail achieves the safest results when multiple layers—control systems, infrastructure, vehicle design, and trained people- support one another.

Focused investments in in-cab signaling systems, positive train control, ERTMS deployments, crossing upgrades, crashworthy rolling stock, and automated inspection deliver measurable reductions in serious incidents.

Strong programs also emphasize passenger emergency alerts and community engagement at interfaces where public behavior drives risk. Treat these measures as a continuous cycle: assess, implement, audit, and improve.